آخرین اخبار

مدیرعامل شرکت توانیر گفت: ساز و کارهای تشویقی برای سرمایه گذاری در نیروگاه های مقیاس کوچک به دنبال ابلاغ مصوبه توسعه مولدهای مقیاس کوچک از سوی وزارت نیرو فراهم شد.

09 بهمن 1402

مشاهده

مدیر پارک علم و فناوری، مدیرکل سازمان صمت و مدیران دانشگاههای دولتی و فنی و حرفهای استان خراسان شمالی روز سهشنبه سوم بهمن ماه از کارخانه فاباموتور در بجنورد بازدید کردند.

07 بهمن 1402

مشاهده

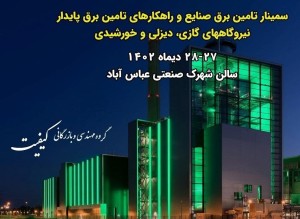

سمینار راهکارهای تامین برق صنایع با هدف آشنایی با دستورالعملهای ابلاغی وزارت نیرو، بورس انرژی و راهکارهای تامین برق پایدار در تاریخهای ۲۷ و ۲۸ دی ماه ۱۴۰۲ در سالن همایشهای شهرکهای صنعتی عباس آباد برگزار خواهد شد.

21 دی 1402

مشاهده